Premium Skid Plate

"Since a stick came through my floorboard during a casual ride on a backcountry road, I refuse to drive my SxS without a skid plate. There is no reason to risk my vehicle or my family." - Gregg (UTV owner since 2005)

BUY ONCE, CRY ONCE. Replace any part and pay factory pricing for replacements if you break or wear it out

MADE IN UTAH: Sourced, Designed, and Manufactured in the USA

WORKMANSHIP GUARANTEE. We will replace any workmanship issue at no cost to you

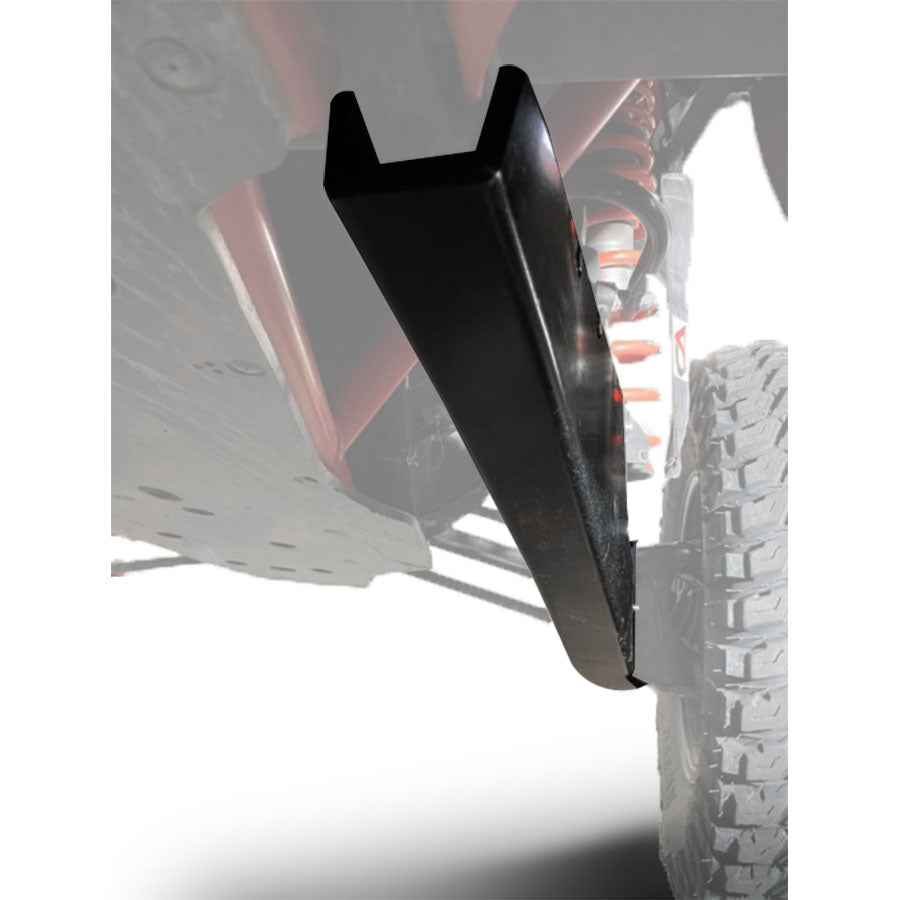

Skid Plate | Premium 3-Piece | UHMW | Can-Am Maverick X3

Best UTV Premium Skid Plate Features for Can-Am Maverick X3

FEATURES

- Will fit XDS, RR, X RS, RC, X MR models

- 3/8 inch thick UHMW

- Recessed bolt holes - smooth, no-snag finish

- Miter Lap joints - near seamless

- Only 3 pieces, Massive 1 Piece Main Panel

- Optional 2.5 inch tall built-in rock sliders

Don't let insurance and a thin, flimsy OEM skid be your first line of defense. An SSS Offroad skid plate will give you the peace of mind you want for your X3.

Our X3 skid plate offer the best protection, material, and fit. This comes with an unbeatable lifetime warranty that only a made in the USA company would offer.

BEST X3 SKID PLATE FEATURES

- Material. UHMW skid plates are slickest and most abrasion resistant plastic available. They also can absorb big impacts. Don't settle for imposter plastic.

- Thickness. 3/8ths inch give you the optimal protection you need without adding unnecessary weight or cost. This thickness wins in the toughest terrain - driven by King of Hammers winners and finishers

- Lap joints. Our miter lap joints create flush overlapping panels with a near seamless finish. We reduce catch points and don't use high risk butt joints!

- Pieces. Our X3 skid plate has 1 massive main panel reducing the chance of catching or tearing off.

- Rock Sliders. Snug fit between the rocker and the machine. It forms to the angle of the machine, not the machine that bent it. Option to be have the rockers built into the skid skid plate.

- Easiest Install. No tapping required and we reuse all available factory holes. Our custom made fasteners are fine threaded screw that automatically tap pre-drilled holes. The fine threads are very important because the frame tubing is so thin.

- Premium Hardware. Best corrosion resistant coating available. Fine threaded screws allow for the strongest frame connection and rounded cup steel washers protect nearly every bolt

- Maintenance. We include essential drain and maintenance holes. If an area is serviced less than once a year, we do not include it and recommend removing the panel to clean and service.

WHY BUY FROM US?

- Made in USA. We design, test, and manufacturer your product in Utah. We also source our materials from US manufacturers.

- Buy once, cry once warranty. Damage or wear out a piece of your skid? You can get a replacement part for an average of 50-70% of the retail value

- Workmanship Guarantee. If there is an issue due to manufacturing, we'll make it right.

- Fit. Cutting edge technology - .1mm accurate 3D scanners, measurement systems, and CNC machines

UHMW FAQs

What is UHMW?

UHMW-PE stands for Ultra-High Molecular Weight Polythene.

High Impact Strength

- Absorbs impacts

- Bounces back to original shape

Extremely Quiet

Significantly dampens impact noise

Self Lubricating/High Abrasion Resistance

- Easily slide over rocks and logs

- Outwears carbon steel 10:1, great for sand

Light-Weight

- Lighter than aluminum

- Very similar weight to HDPE (Factory/OEM material)

Why is our material the better than others?

We only supply genuine American made UHMW-PE.

We believe some products pose as UHMW based but are not made from UHMW. Some material descriptions that we believe you should be aware of are:

- "Proprietary blend of UHMW" (most likely HDPE or HMW)

- HMW (less than 10x the molecular weight of UHMW)

- ARMW (most likely HMW)

Which UHMW material thickness should I choose?

3/8th inch UHMW is the best material thickness for nearly all riders.

- 1/8th inch won't allow for a flat finish, hardware or lap joints

- 1/2 inch adds unnecessary weight, doesn't add meaningful upgrade in protection

Why we don't use colored UHMW?

UHMW colors are very limited and primarily used for utility applications, not cosmetic applications. This means that color shades can have significant variations from sheet-to-sheet and will not be matched to a specific Pantone (color matching system). If you have seen cool colored plastics, they are most likely not UHMW because of the inability to color match.

Strength of UHMW vs other plastics?

UHMW has more than 10x the molecular weight than it's little brother HMW (some might call it ARMW). This is what gives UHMW it's superior impact strength, abrasion resistance, stress/crack resistance, and more! This makes it very important to prioritize material type/authenticity over material thickness.

Why factory skids don't cut it?

- Most Factory/OEM skids provide minimal protection

- Factory skids are made with plastic that easily cracks, punctures, or breaks

- Too Thin or Too Thick

- Too many needless holes add snag points