Cargo Rack / Dog Seat

"Since a stick came through my floorboard during a casual ride on a backcountry road, I refuse to drive my SxS without a skid plate. There is no reason to risk my vehicle or my family." - Gregg (UTV owner since 2005)

BUY ONCE, CRY ONCE. Replace any part and pay factory pricing for replacements if you break or wear it out

MADE IN UTAH: Sourced, Designed, and Manufactured in the USA

WORKMANSHIP GUARANTEE. We will replace any workmanship issue at no cost to you

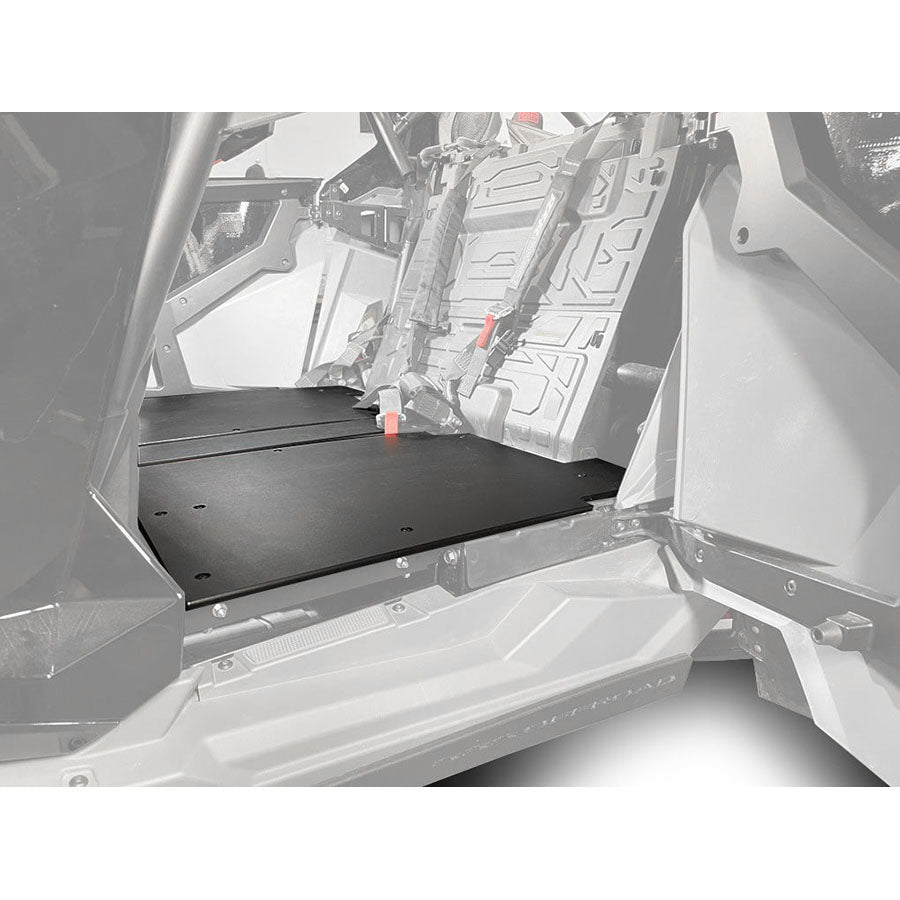

Cargo Rack / Dog Seat - Back Seat Conversion Kit | Polaris RZR Pro XP 4

Best UTV Cargo Rack / Dog Seat Features for Polaris RZR Pro XP 4

Features

- Access to foot opening for extra storage

- Easy and fast install and uninstall

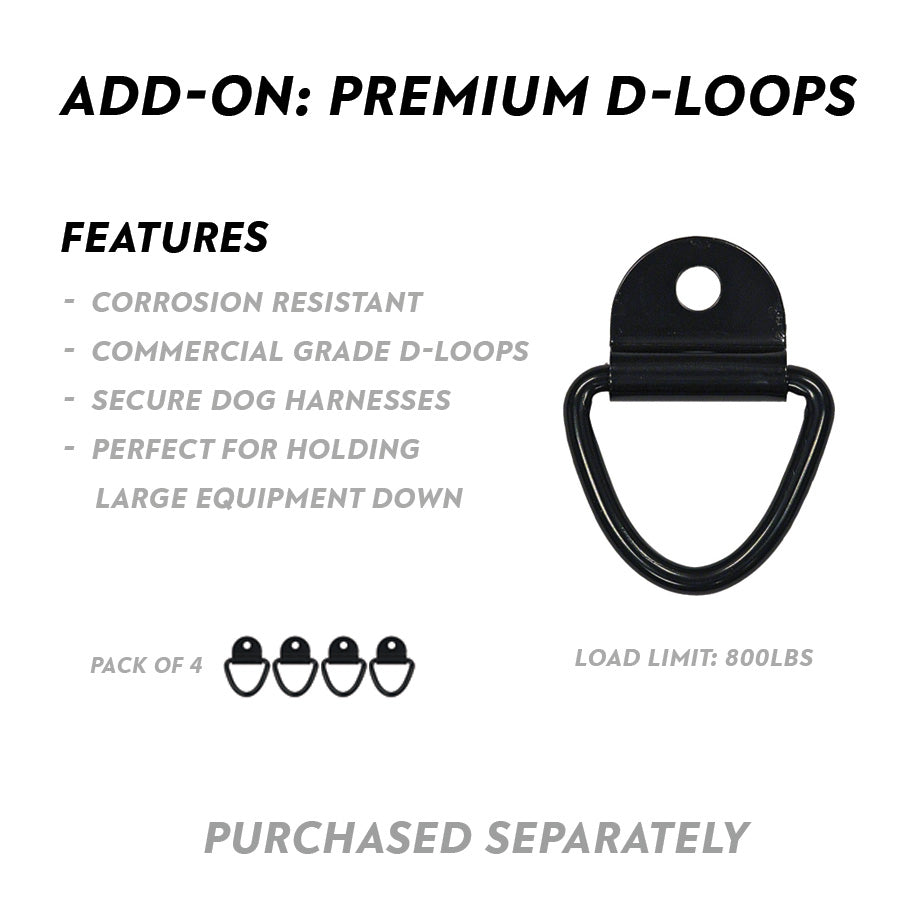

- Easily tie down your cargo with D loops (purchase separately) - you can install loops anywhere on the platform

Includes (per side)

- Base Kit for Seat Conversion (installs in seconds)

- NOTE: Ultimate - Pro R 4: Cargo rack base is not included, model features flip down seat. Installs on top of folded seats for a flat surface

- Cargo Rack Platform

- Hardware

Optional

How to choose between HDPE and UHMW

For most consumers, HDPE provides the best features for the price along with the most attractive material finish.

Our HDPE has a matte black finish and our UHMW has a shinny finish.

UHMW can be up to 10x the molecular strand length as HDPE. This enables UHMW to be even more durable and abrasion resistant than HDPE. However, the unique manufacturing process that is needed to achieve UHMW’s performance leads to a higher material price and a less consistent color/texture.

|

HD-PE |

UHMW-PE |

|

|

Full Name |

High Density Polyethylene |

ULTRA High Molecular Weight Polyethylene |

|

Our recommendation |

Not sold or recommended for most offroad applications |

Best for heavy use offroad riders |

|

Cost |

$$ |

$$$$ |

|

Impact Strength |

Good |

Best/No Break |

|

Friction Rating |

Slippery |

Extremely Slippery |

|

Abrasion Resistance |

Good |

Best |

|

Appearance |

Excellent, no variations in color or texture |

Good, slight variations in color and texture, black |

|

Best Use |

- Low use

|

- High use |

|

Description |

Extremely common plastic that is easy to form into consumer items |

Extremely durable, wear resistant, self lubricating industrial plastic |

What our friends say

Timeline (Jump to)

1:00 - Intro to the cargo rack

1:38 - Assembling the kit

3:11 - Installing into the machine - seconds to install

4:01 - Difference between competitors / Seat Base

4:45 - Difference between UHMW and HMW

5:10 - Strength Test

6:30 - Dog test

Compatibility Notes

If you have custom seats, you can adjust the edges by cutting the plastic with a jigsaw or circular saw. Cutting instructions come with your purchase.

Still have questions? Request Model Verification by our staff or Contact Us!

UHMW FAQs

What is UHMW?

UHMW-PE stands for Ultra-High Molecular Weight Polythene.

High Impact Strength

- Absorbs impacts

- Bounces back to original shape

Extremely Quiet

Significantly dampens impact noise

Self Lubricating/High Abrasion Resistance

- Easily slide over rocks and logs

- Outwears carbon steel 10:1, great for sand

Light-Weight

- Lighter than aluminum

- Very similar weight to HDPE (Factory/OEM material)

Why is our material the better than others?

We only supply genuine American made UHMW-PE.

We believe some products pose as UHMW based but are not made from UHMW. Some material descriptions that we believe you should be aware of are:

- "Proprietary blend of UHMW" (most likely HDPE or HMW)

- HMW (less than 10x the molecular weight of UHMW)

- ARMW (most likely HMW)

Which UHMW material thickness should I choose?

3/8th inch UHMW is the best material thickness for nearly all riders.

- 1/8th inch won't allow for a flat finish, hardware or lap joints

- 1/2 inch adds unnecessary weight, doesn't add meaningful upgrade in protection

Why we don't use colored UHMW?

UHMW colors are very limited and primarily used for utility applications, not cosmetic applications. This means that color shades can have significant variations from sheet-to-sheet and will not be matched to a specific Pantone (color matching system). If you have seen cool colored plastics, they are most likely not UHMW because of the inability to color match.

Strength of UHMW vs other plastics?

UHMW has more than 10x the molecular weight than it's little brother HMW (some might call it ARMW). This is what gives UHMW it's superior impact strength, abrasion resistance, stress/crack resistance, and more! This makes it very important to prioritize material type/authenticity over material thickness.

Why factory skids don't cut it?

- Most Factory/OEM skids provide minimal protection

- Factory skids are made with plastic that easily cracks, punctures, or breaks

- Too Thin or Too Thick

- Too many needless holes add snag points