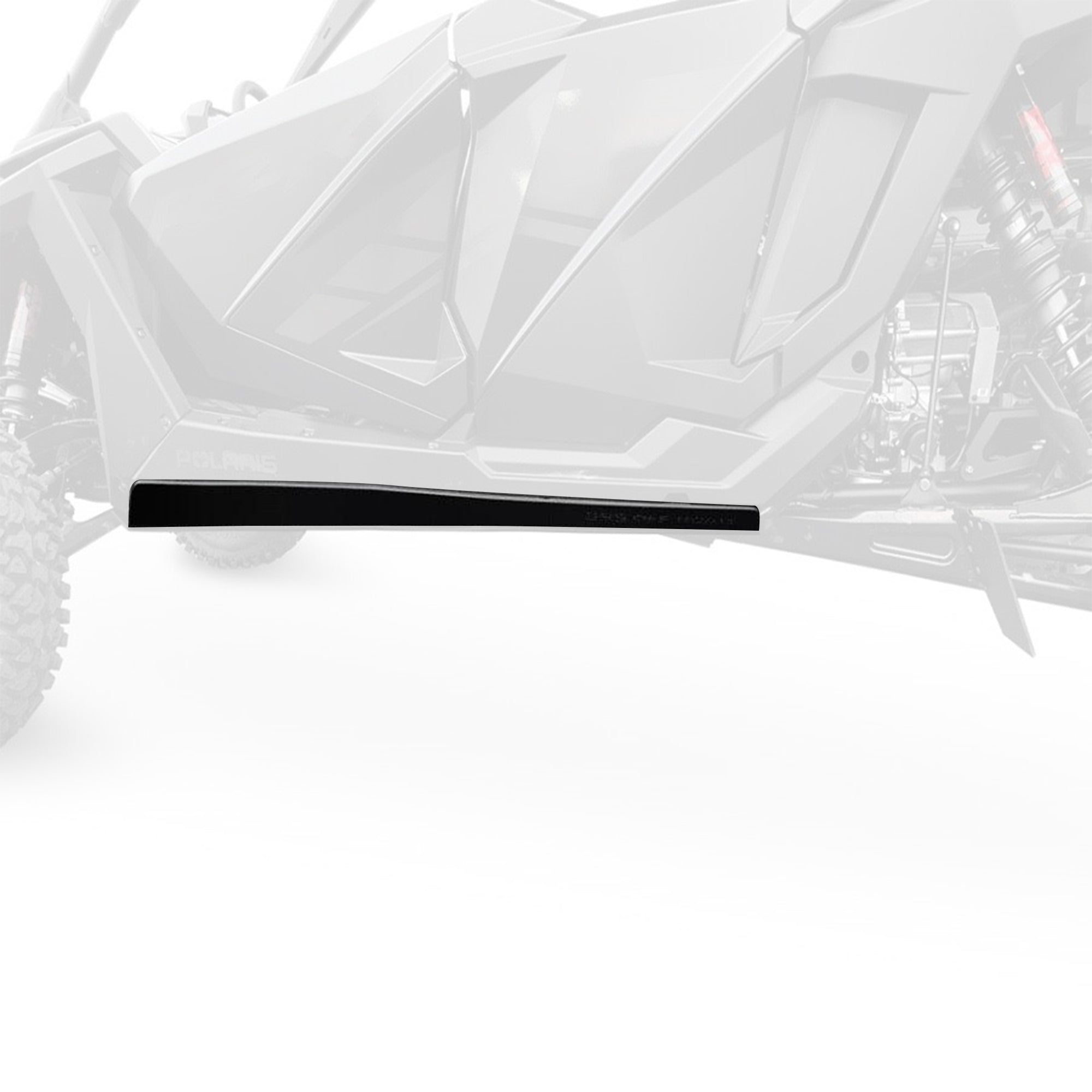

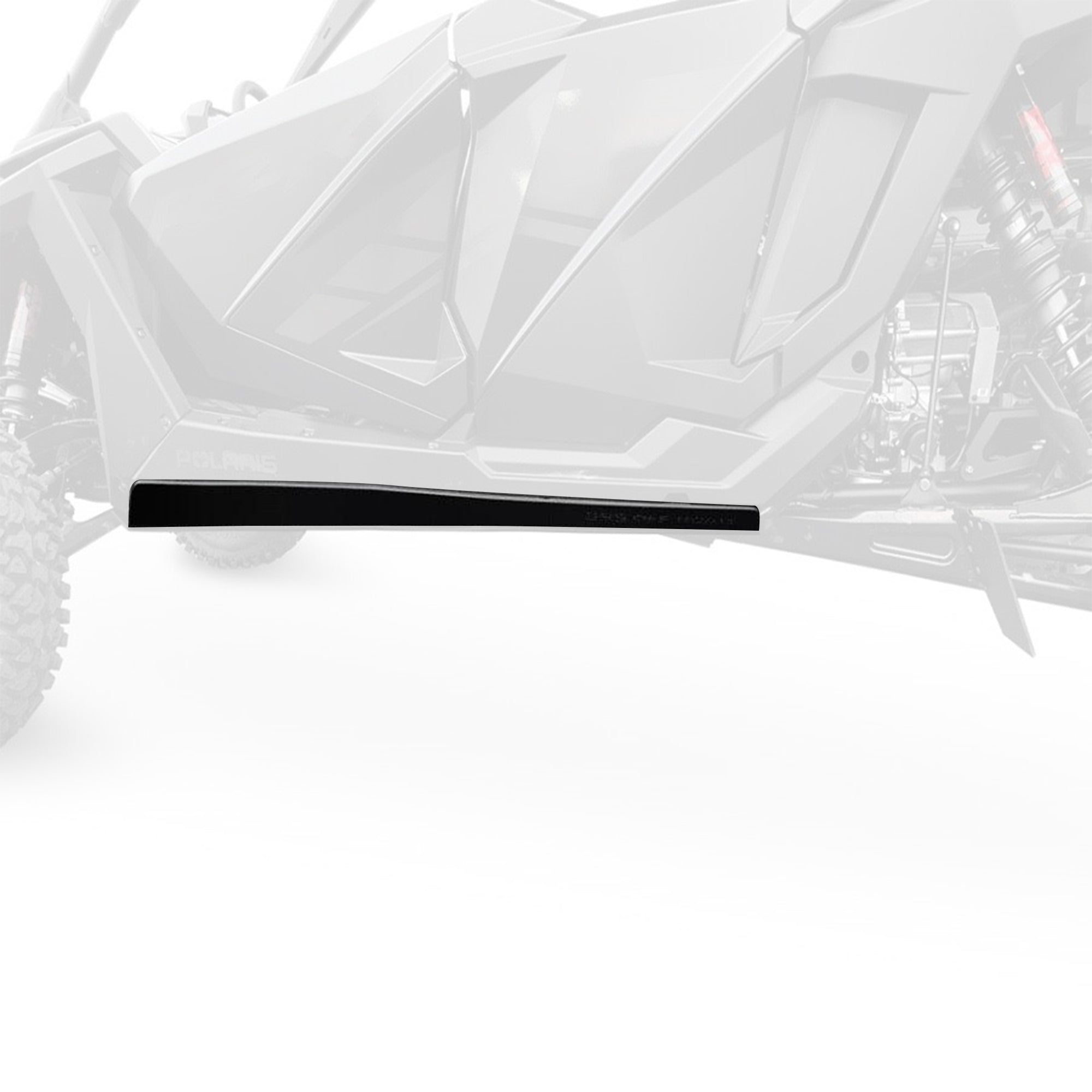

Rock Sliders

UHMW Rock Sliders | Polaris RZR Pro XP 4 by SSS Offroad

SSS Off-Road single piece, rock slider protectors are a must for all UTV enthusiasts who value their investments, the people they ride with, as well as their machines.

This product complements factory and aftermarket skid plates alike, to provide you that full side protection from rocks and other obstacles during your ride, giving you that peace of mind you deserve.

SSS Offroad Rock Sliders are a standalone upgrade, designed to install with or without our full UTV skid plate system. They deliver superior side panel protection, strength, and durability on any terrain.

FEATURES

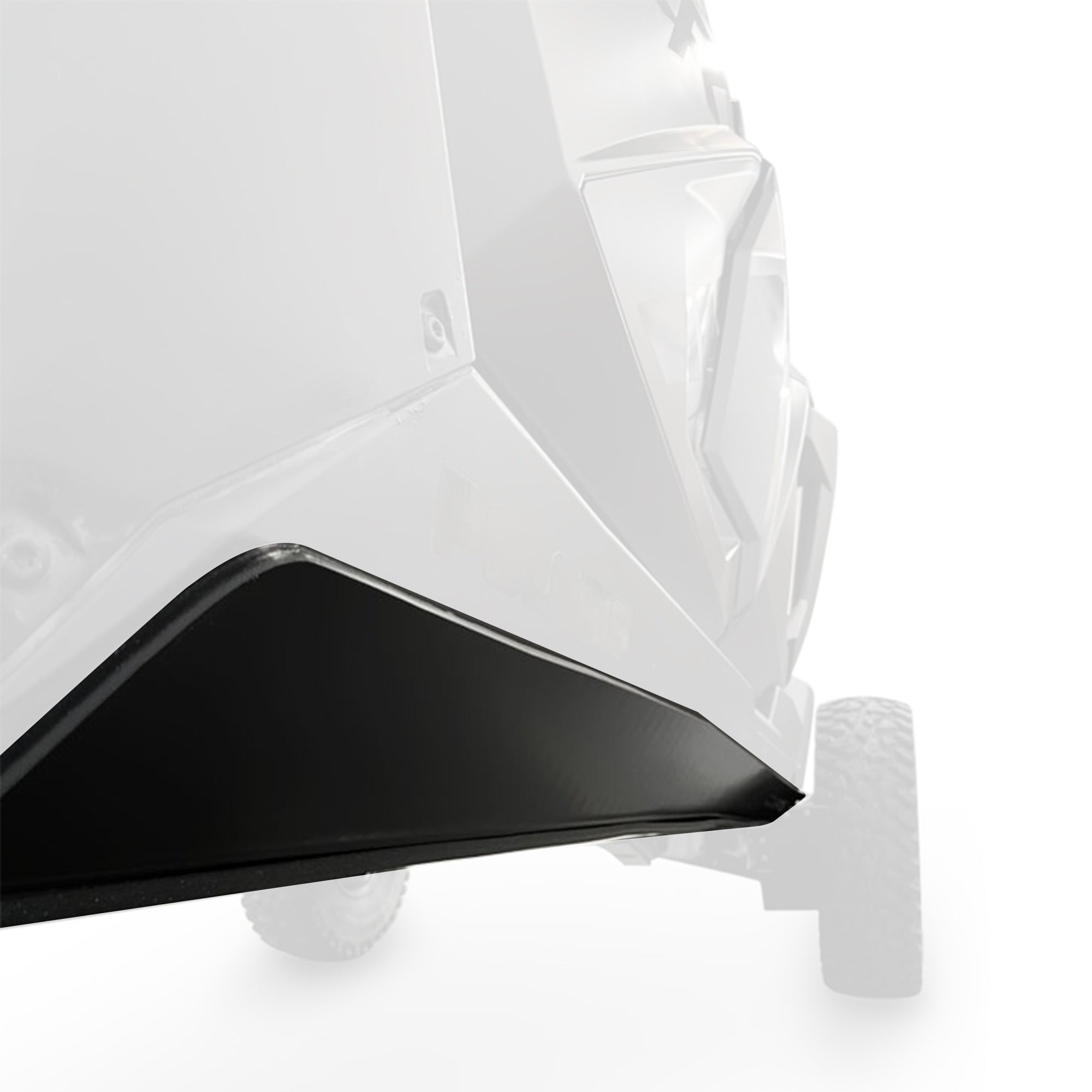

- Constructed of 3/8" thick, 100% UHMW material that's built to last

- Much more durable and scratch & dent resistant than aluminum side rockers

- Recessed bolt holes for flushed hardware that allows for a smooth, no-snag finish

- Performance-grade hardware kit included with step-by-step installation instructions

- Maintain ground clearance

COMPATIBILITY

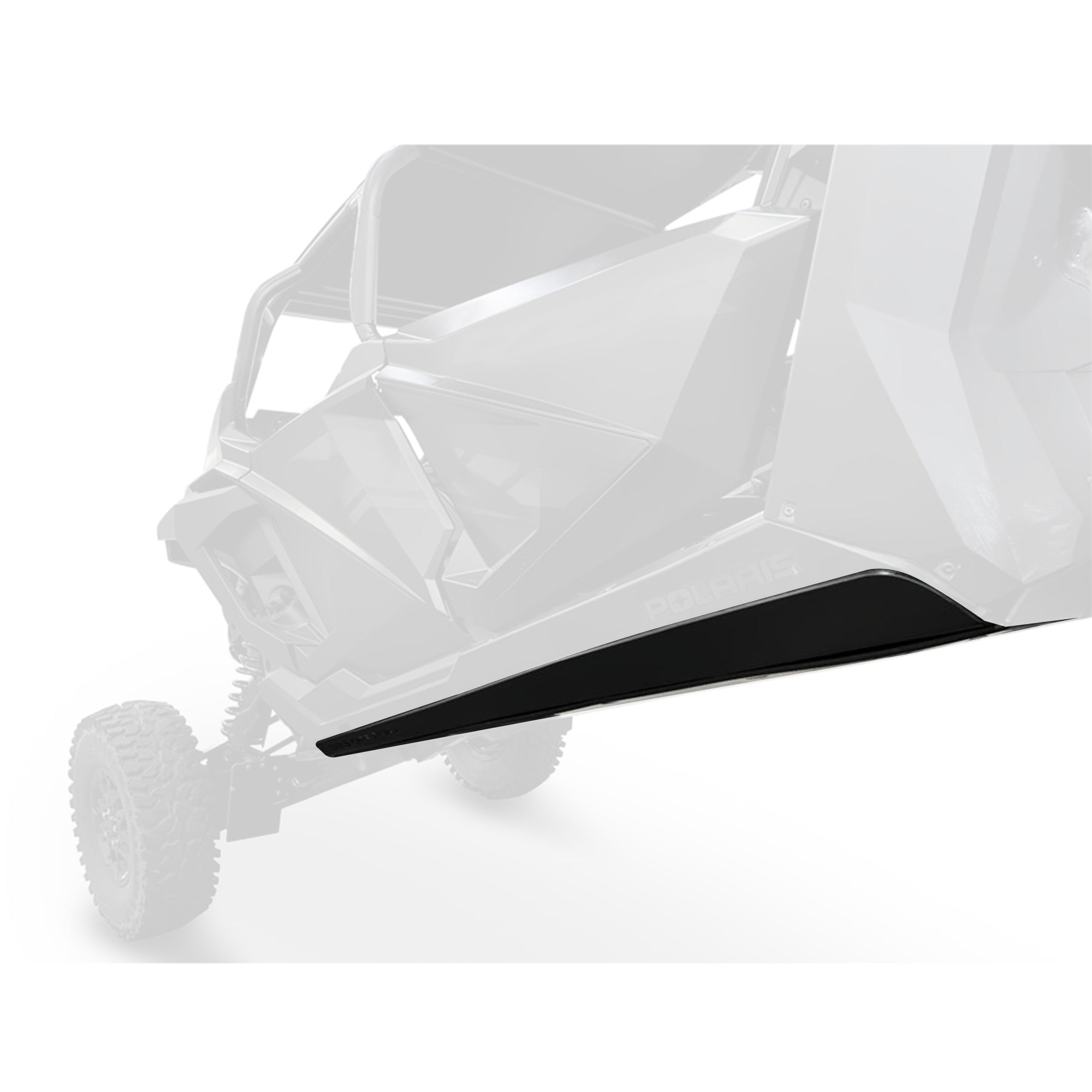

-

UHMW Rock Sliders fit all 2024 RZR Pro XP 4 models and earlier years/models.

-

Metal rock sliders, aka "rock catchers" require custom/permanent adjustments

UHMW FAQs

What is UHMW?

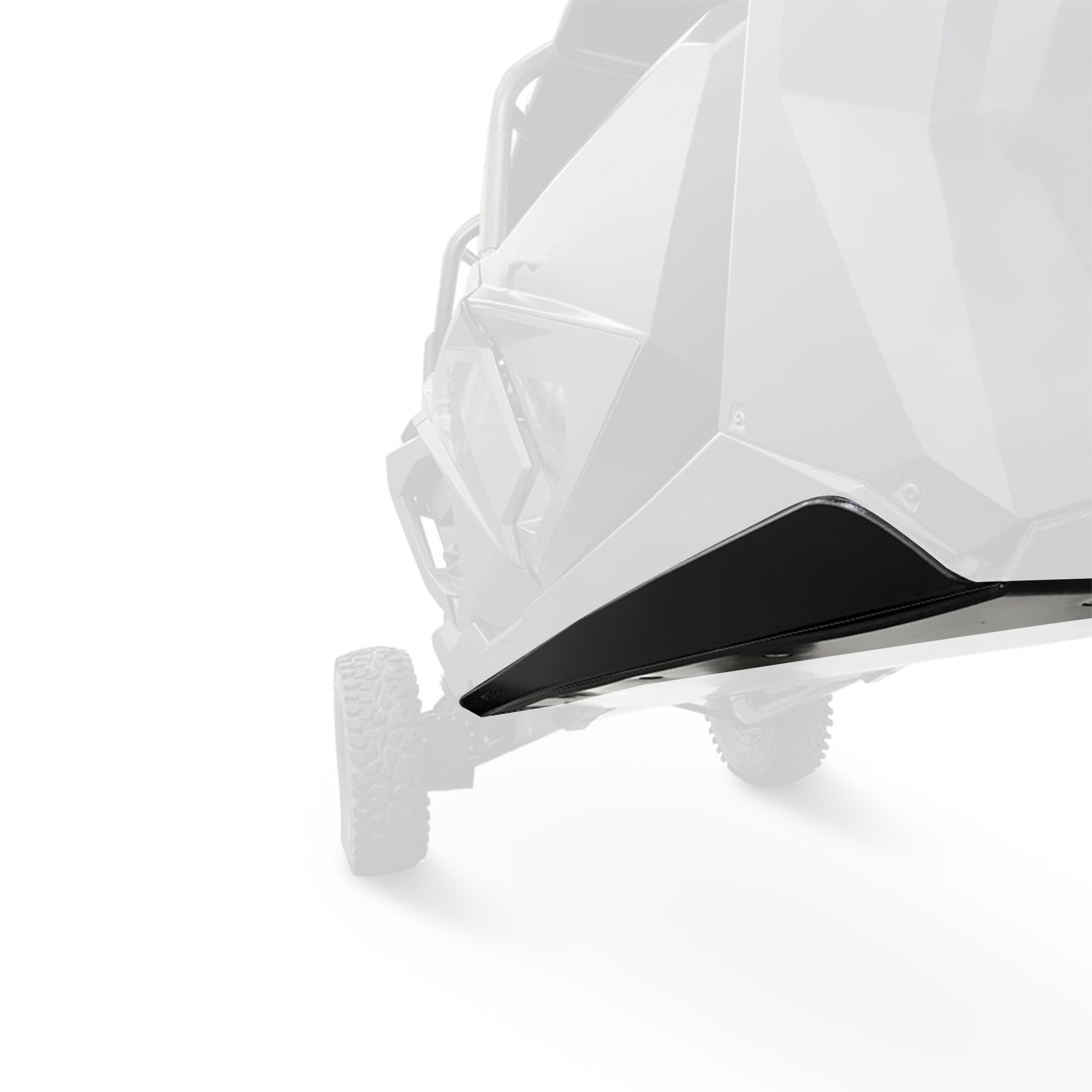

UHMW-PE stands for Ultra-High Molecular Weight Polythene.

High Impact Strength

- Absorbs impacts

- Bounces back to original shape

Extremely Quiet

Significantly dampens impact noise

Self Lubricating/High Abrasion Resistance

- Easily slide over rocks and logs

- Outwears carbon steel 10:1, great for sand

Light-Weight

- Lighter than aluminum

- Very similar weight to HDPE (Factory/OEM material)

Why is our material the better than others?

We only supply genuine American made UHMW-PE.

We believe some products pose as UHMW based but are not made from UHMW. Some material descriptions that we believe you should be aware of are:

- "Proprietary blend of UHMW" (most likely HDPE or HMW)

- HMW (less than 10x the molecular weight of UHMW)

- ARMW (most likely HMW)

Why we don't use colored UHMW?

UHMW colors are very limited and primarily used for utility applications, not cosmetic applications. This means that color shades can have significant variations from sheet-to-sheet and will not be matched to a specific Pantone (color matching system). If you have seen cool colored plastics, they are most likely not UHMW because of the inability to color match.

Strength of UHMW vs other plastics?

UHMW has more than 10x the molecular weight than it's little brother HMW (some might call it ARMW). This is what gives UHMW it's superior impact strength, abrasion resistance, stress/crack resistance, and more! This makes it very important to prioritize material type/authenticity over material thickness.

Why factory skids don't cut it?

- Most Factory/OEM skids provide minimal protection

- Factory skids are made with plastic that easily cracks, punctures, or breaks

- Too Thin or Too Thick

- Too many needless holes add snag points